#Industry News

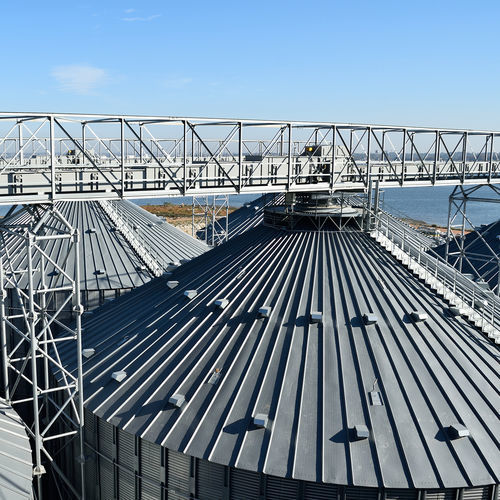

Corn Storage Facility Installation Begins in Bolivia

The instalation includes steel silos, ventilation systems, catwalks, and a fully mechanized system.

We have started the installation of a new corn storage facility in Bolivia, featuring metal silos, ventilation systems, catwalks, and a fully mechanized system designed to maximize grain handling efficiency, enabling seamless loading, unloading, and preservation of corn under optimal conditions.

High-quality silos and equipment

The facility will include silos of various capacities, suited for both large-scale storage and efficient, controlled grain handling. It will include two flat bottom silos, with a capacity of 2,000 m³ each, as well as farm silos and bulk loading silos of different sizes, reaching a total capacity of 4,500 m³. All silos and accessories are constructed with ProMag-coated sheet metal, an innovative aluminum, magnesium, and zinc alloy that provides exceptional corrosion resistance, even in challenging environments. This coating enhances durability and reduces maintenance costs, offering a significant long-term operational benefit.

Ventilation and temperature monitoring system

To ensure the quality of stored corn, the facility is equipped with an advanced ventilation and temperature monitoring system. Ventilation grates and fans enable the consistent airflow, essential to prevent moisture buildup and protect the grain. Additionally, temperature probes are installed to monitor silo conditions, enabling swift responses to any changes and ensuring optimal product preservation.

Efficient grain handling equipment

The mechanized loading and unloading system is designed to handle large volumes of corn efficiently. With bucket elevators, belt conveyors, sweep augers, screw conveyors, discharge hoppers, and slide gates, the system enables fast and secure grain movement, optimizing material flow and minimizing downtime throughout the facility.

Catwalks and support structures

A network of catwalks and support structures will provide easy access to all areas of the silos, enhancing safety and facilitating maintenance. Reinforced supports ensure the stability of the entire facility.

The combination of high-strength ProMag-coated sheet metal and advanced mechanization ensures that the facility is ready to meet storage demands efficiently and sustainably for the long term.