#Farm Machinery & Equipment

Mechanical Blueberry Harvester Can Save on Labor

Reduce costs by 80%

By using JAGODA 300 the mechanical blueberry harvester can reduce costs by 80% and improve labor productivity.

In order to harvest the blueberry bush, several actions need to be made during planting to reduce the losses of fruits below 8%. JAGODA 300 blueberry harvester achieved a new record by minimizing the loss of fruit compared to other harvesters in the market.

- The most important is the bed configuration: JAGODA 300 blueberry harvester has low catcher plates around 25 cm to 30 cm from the level of the ground, with bed configuration around 25 cm to 30 cm the catch plates closer to the base of the crown of the blueberry bush. (Fig. 1)

- The crown has to be narrow to minimize the loss of the fruit. Wide crowns increase the loss when the catcher plates open around the bush. (Fig. 2)

- Removing any low-hanging shoots from 35 cm of the plant.

- Spacing between rows should be a minimum of 2.5 m to 3 m (Fig.3)

- Spacing at the end of the row to be around 6 m to 8 m. ( harvester equipped with steering wheels, which provides a small turning radius, which is especially important on u-turns.

- Spacing between plants around 60 cm to 90 cm (depending on the field and blueberry variety that is related to the size of the bush )

The advantages of tow-behind over-the-row blueberry harvester JAGODA 300 versus hand harvest :

- Can harvest a high capacity of fresh and processed fruits.

- Reduce the need for labor.

- Minimizes the cost of harvest, the tow behind is much cheaper than self-propelled and within one season the harvester pays back to the farmer that has few hectares of plantation.

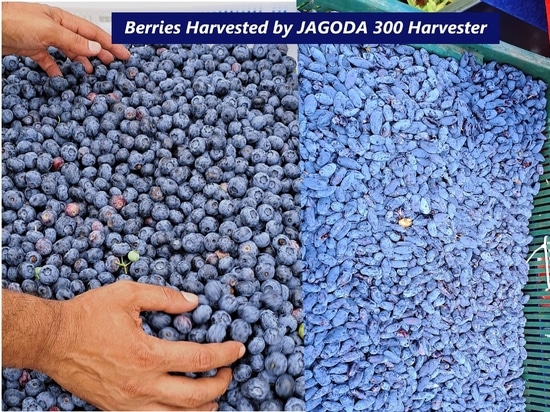

Minimizing the fruit bruising with JAGODA 300 berry harvester:

All the bruising fruits in mechanical harvest due to the fruit falling from a distance to a hard surface to conveyors and catcher plates.

The last year 2022, we tested the harvester on different plantation conditions and different blueberry varieties to show the potential of the harvester in front of berry growers.

Recently, we are working on new catcher plates and new layers to be softer when the fruit touches the surface.

The harvester is characterized by high-quality workmanship and modular construction:

- Less compaction on soil with a lightweight design.

- Collecting fruits from the low shrubs with minimum losses

- Innovative vertical shaker head 920 that allows to adjust and regulate the shaking force on the bushes.

- An effective system for clean fruits. High cleaning system designed to remove leaves and impurities from receiving collected fruits by conveyor, controlled hydraulically, and has adjustable speeds up to 1000 turn/min.

- Requires a minimum 70 hp tractor with 540 rpm PTO. suitable for continuous operation even at high temperature

- Multiple configurations of storage fruits

- A hydraulic platform for collecting fruits ( transport and working position)

- Hydraulic adjustable picking tunnel to fit different plantation conditions ( Height: 2945 mm – 3575 mm)

- Drive and working light

- Protection roofs

- Steering wheels

- Harvesting carried out with or without the T-shaped support posts

- Wireless control panel ( Up to 80 meters)

To find out if your blueberry farm is suitable for mechanical harvesting, feel free to contact us.

We can help you to choose the solution that can fit your plantation!