#Industry News

How to save water and fertilizers with high-precision irrigation

Water and fertilizer waste is one of the biggest challenges facing farmers and irrigation companies today.

Traditional systems, based on sprinklers or pipes with multiple connections, cause losses due to evaporation, runoff, and leaks, increasing operating costs and compromising the sustainability of the operation. Faced with this reality, high-precision drip irrigation emerges as the most effective solution: by ensuring uniform and controlled distribution of the flow directly to the roots of each plant, it minimizes resource consumption and maximizes yield.

In this article, we’ll discover how a system designed by a leading irrigation system manufacturer can transform your investment in water and fertilizers into a real savings and profitability factor.

Flow uniformity in precision irrigation systems

Distribution uniformity refers to a drip irrigation system’s ability to deliver the same amount of water and nutrients to each plant, regardless of its position in the irrigation line. This parameter is key because any variation in flow rate can create excessively wet or dry areas, causing water stress, uneven growth, and yield losses.

In our systems, we use state-of-the-art drippers—MOP, ND, and NDH—designed to operate optimally between 0.7 and 3.5 bar, with flow rates ranging from 1.1 to 11 l/h. Thanks to this versatility, each dripper maintains a stable and precise flow, even when water pressure varies. For example, MOP (Medium Operating Pressure) drippers offer constant flows of 1.1–8 l/h, while ND (No-Drain) and NDH (No-Drain High) models guarantee 1.1–11 l/h with no residual drip losses.

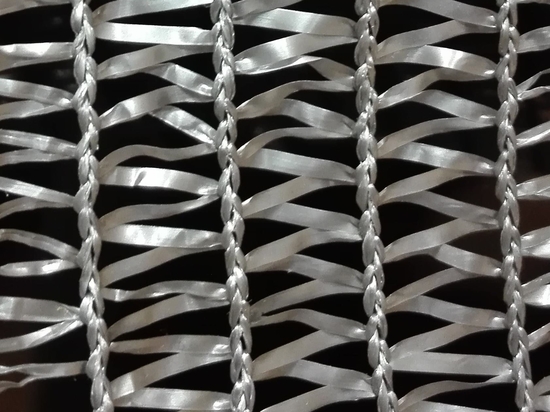

Furthermore, the 3×5 mm and 4×6 mm PVC microtubes play a key role: their sturdy structure prevents kinks and blockages, which are common with flexible tubes. By preventing deformation, they ensure a continuous and uniform flow to each dripper. These microtubes resist sunlight exposure and the chemicals found in fertilizers, prolonging their lifespan and maintaining hydraulic efficiency.

The combination of calibrated drippers and reliable PVC microtubing ensures flow uniformity, a cornerstone of any irrigation system manufacturer and retailer looking to offer high-performance solutions.

Economic impact and sustainability

Adopting a high-precision drip irrigation system can result in water and fertilizer savings of up to 30–60% compared to conventional irrigation methods. By delivering only the exact amount of resources each plant requires, losses due to runoff and evaporation are eliminated, directly resulting in lower bills. For example, in a one-hectare tomato crop, reducing water consumption by 30% can save tens of thousands of liters per month, and precise fertilizer dosing prevents costly overdosing.

This lower operating expense drives a better return on investment (ROI): the irrigation system itself quickly pays for itself on many farms thanks to reduced input and labor costs. Furthermore, the fully assembled or modular design minimizes field installation time, reducing technical expenses and enabling faster production start-up.

Sustainability is another major benefit: by optimizing water use, we contribute to preserving an increasingly scarce resource; and by avoiding excessive fertilization, we reduce the leaching of nutrients into the soil and groundwater. Finally, the system’s durability is guaranteed by the use of high-quality materials and the absence of intermediate couplings, which prevents leaks and prolongs the lifespan of the installation, reducing the need for frequent replacements and generating even more savings in the long run.

Practical advantages for the farmer and the technical buyer

One of the great advantages of our high-precision irrigation system is its ultra-fast installation, requiring no specialized labor. Thanks to the pre-assembled lines, farmers can connect tubing, microtubes, and drippers in a matter of hours, avoiding weeks of assembly time and significantly reducing field technician costs.

The modular or 100% pre-assembled design ensures minimal maintenance: with no intermediate couplings or leak-prone joints, maintenance is limited to occasional checks on drippers and filters, rather than constant repairs. This frees up time and resources, allowing central purchasing managers and greenhouse managers to focus on crop management rather than maintenance tasks.

Furthermore, flexibility is complete: if a turnkey solution is required, simply request complete pre-assembled lines, adapted to the length of each corridor. For very specific projects or partial expansions, individual components—pipes, stakes, microtubes, and drippers—can be purchased and the system assembled to measure. This versatility makes the product an ideal choice for both established irrigation companies and individual farmers who demand precision and speed.

Request your quote and trust the experts

Don’t miss the opportunity to optimize your irrigation and save money with every harvest. Request a free quote at info@hydroponicsystems.es and discover why Hydroponic Systems is the most trusted manufacturer and seller of irrigation systems on the market.

Transform your crops with maximum precision and efficiency!